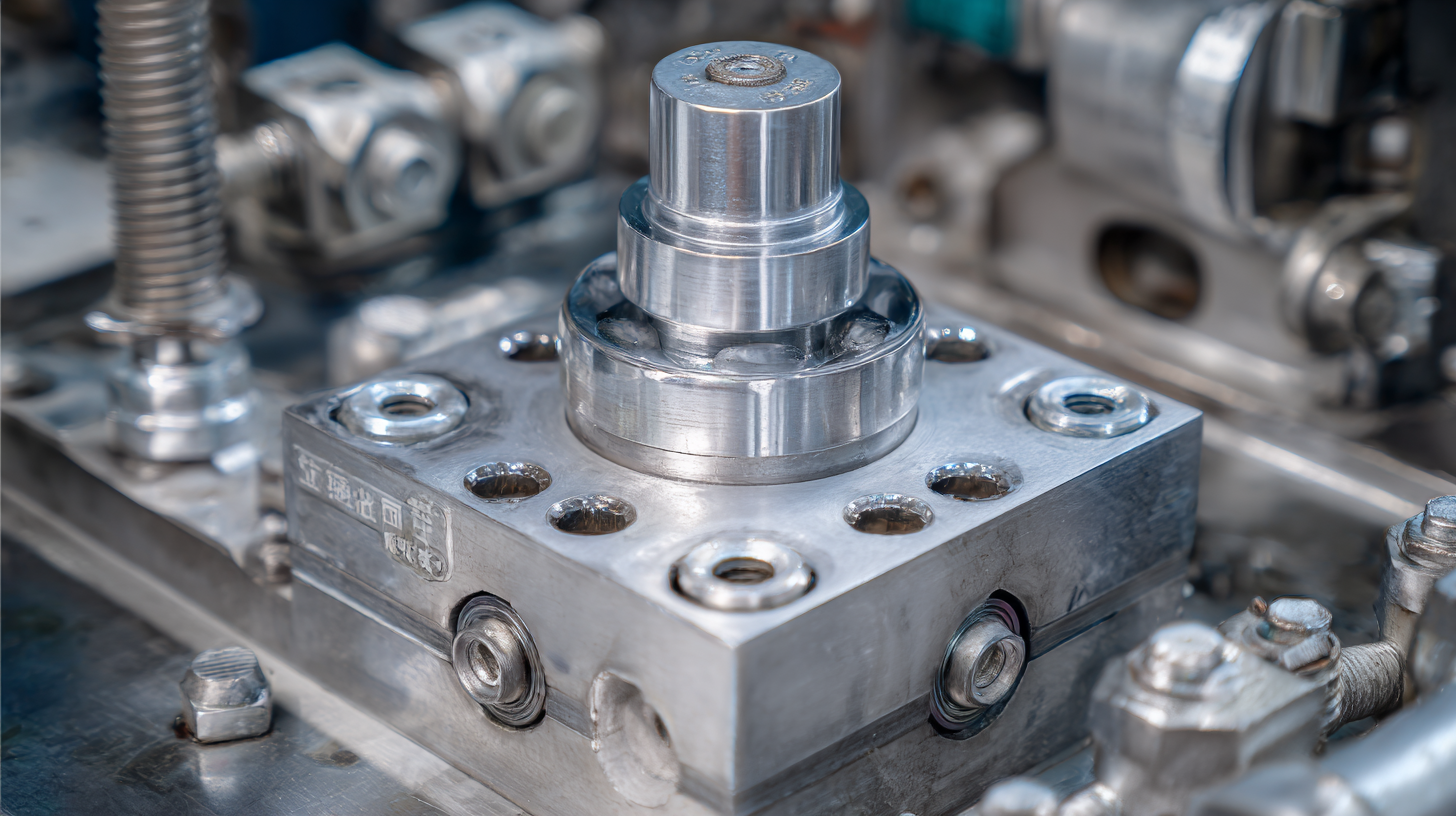

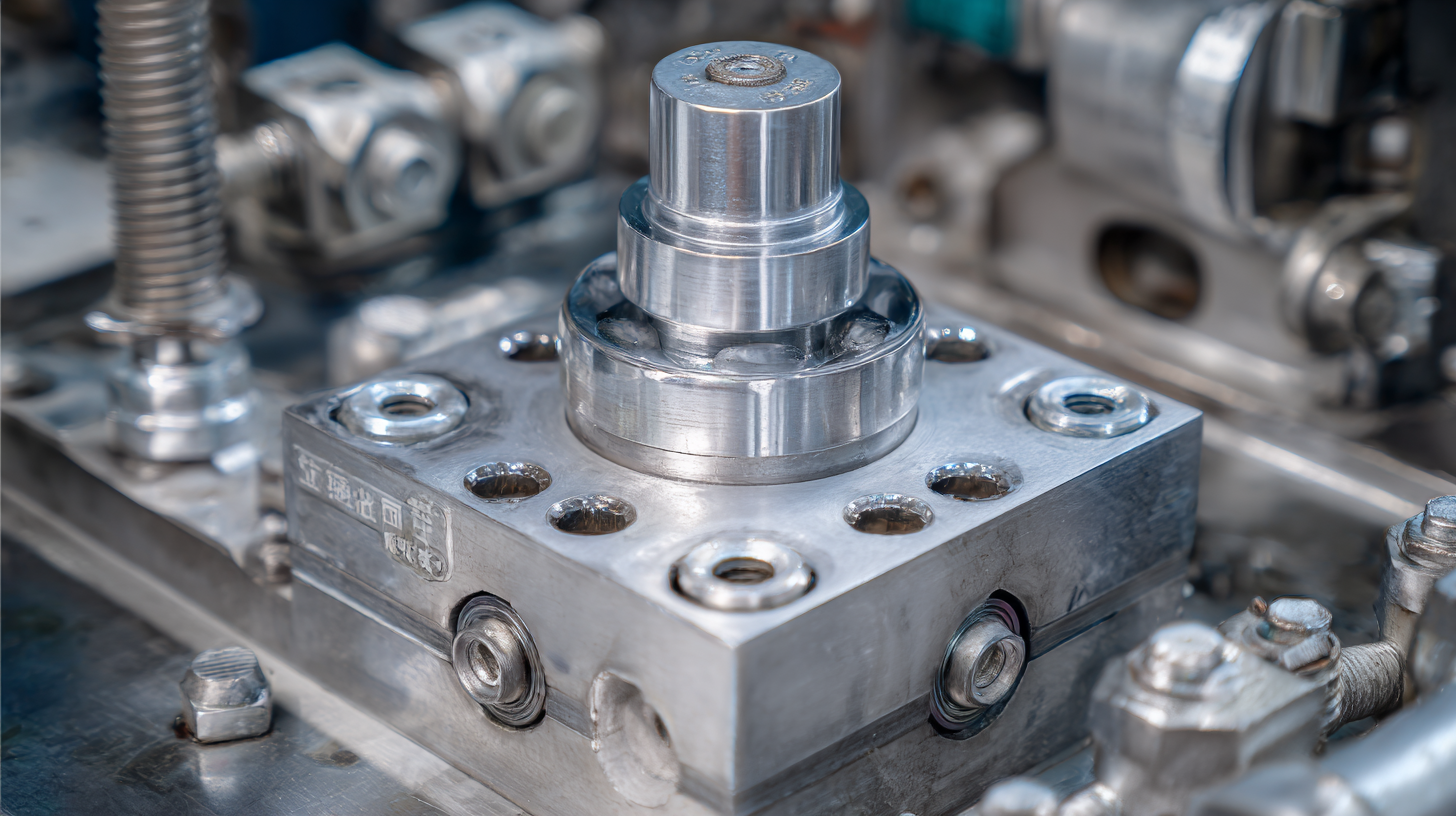

Craftsmanship in Every Detail China Made Bypass Valve Setting Global Standards

In the evolving landscape of industrial manufacturing, the significance of high-quality components like the bypass valve cannot be overstated. According to a recent MarketsandMarkets report, the global bypass valve market is projected to reach USD 8.1 billion by 2025, growing at a CAGR of 5.3% from 2020. This growth underscores the critical role of precision engineering and craftsmanship in developing reliable valve systems that can withstand diverse operational challenges.

China has made remarkable strides in this arena, establishing itself as a leader not only in production volume but also in setting stringent quality standards that align with international norms. The emphasis on craftsmanship in every detail ensures that Chinese-made bypass valves are not merely functional components but also benchmarks of durability and performance in today's global marketplace.

Significance of Bypass Valves in Modern Industries

Bypass valves are crucial components in many modern industrial applications, serving as safety mechanisms that enhance performance and efficiency. Their function is particularly vital in systems such as HVAC, automotive, and power generation. As industries strive to meet rapidly evolving demands, the significance of bypass valves has only increased. For instance, in automotive systems, bypass valves help manage engine temperature and pressure, ensuring optimal performance and preventing overheating.

Recent trends highlight the growing reliance on advanced technologies that incorporate these valves. Industry reports suggest that by 2025, around 70% of new automotive models will utilize sophisticated thermal management systems, where bypass valves are integral. Such systems not only enhance energy efficiency but also support the shift toward electrification and fuel efficiency, aligning with global sustainability goals. The role of bypass valves extends beyond just performance; they contribute substantially to the safety and reliability of mechanical systems across various sectors.

Moreover, with the rise of innovations in turbocharging, the application of bypass valves is expected to expand further. Industry forecasts indicate that vehicles equipped with turbochargers will continue to rise, with projections stating that at least half of new vehicles in certain markets will feature them by 2022. This trend will drive demand for high-quality bypass valves that can support the complexities of modern engine designs, solidifying their importance in both traditional and emerging markets.

Craftsmanship in Every Detail: China Made Bypass Valve Setting Global Standards - Significance of Bypass Valves in Modern Industries

| Dimension |

Value |

Significance |

| Material Quality |

High-grade stainless steel |

Ensures durability and resistance to corrosion |

| Pressure Ratings |

Up to 300 psi |

Fits various industrial applications requiring high pressure |

| Temperature Range |

-30°C to 120°C |

Suitable for diverse operating environments |

| Certification |

ISO 9001, CE |

Assures compliance with international quality standards |

| Applications |

Oil & Gas, Water Treatment |

Critical components for operational efficiency |

Innovative Features of China-Made Bypass Valve Designs

China's innovation in industrial valve manufacturing is rapidly setting new benchmarks, particularly with the advent of the latest bypass valve designs. These valves, integral to various applications in oil and gas, water treatment, and HVAC systems, showcase an impressive blend of cutting-edge technology and craftsmanship. According to a recent industry report by ValvTechnologies, the global bypass valve market is projected to reach $3.5 billion by 2027, with significant contributions from Chinese manufacturers who prioritize both durability and efficiency.

One of the standout features of modern China-made bypass valves is their enhanced flow characteristics. Utilizing advanced computational fluid dynamics (CFD) during the design process, manufacturers are able to optimize valve geometry, resulting in lower pressure losses and improved flow rates. Additionally, many new designs incorporate smart technology, enabling real-time monitoring and control, which enhances operational reliability and predictive maintenance. According to a report from Transparency Market Research, this integration of IoT in valve systems could potentially reduce operational costs by up to 20%.

**Tips:** When selecting a bypass valve for your application, consider models that offer customizable design features to better fit your specific operational needs. Additionally, keep an eye on valves equipped with smart technology; they can provide invaluable data that helps in making informed decisions about system efficiency and maintenance schedules. Always consult recent performance reports to ensure you're making an informed choice.

Quality Control Standards for Bypass Valves in Manufacturing

The manufacturing of bypass valves has seen a significant transformation in quality control standards, particularly in China. As the global demand for high-performance valves rises, manufacturers are increasingly focusing on meticulous craftsmanship to meet these expectations. This commitment to quality is underscored by stringent processes that encompass every step of production, from material selection to final inspections. By implementing advanced testing methods and adhering to international quality standards, Chinese manufacturers ensure that their bypass valves not only perform reliably but also extend the lifespan of crucial systems.

The manufacturing of bypass valves has seen a significant transformation in quality control standards, particularly in China. As the global demand for high-performance valves rises, manufacturers are increasingly focusing on meticulous craftsmanship to meet these expectations. This commitment to quality is underscored by stringent processes that encompass every step of production, from material selection to final inspections. By implementing advanced testing methods and adhering to international quality standards, Chinese manufacturers ensure that their bypass valves not only perform reliably but also extend the lifespan of crucial systems.

Moreover, the integration of modern technology in manufacturing processes has revolutionized the oversight of quality control. Automated systems and data analytics play a critical role in monitoring the production line, allowing for real-time adjustments and ensuring compliance with quality benchmarks. These innovations help identify potential issues early in the production process, reducing waste and enhancing overall efficiency. The dedication to achieving global quality standards positions China as a leader in the bypass valve market, setting a benchmark for excellence that other manufacturers aspire to emulate.

Case Studies: Successful Implementations of Bypass Valves

The implementation of bypass valves has seen transformative success across various industries, setting a benchmark in efficiency and reliability. According to a recent report by Grand View Research, the global valve market is projected to reach USD 83.4 billion by 2025, driven significantly by advancements in manufacturing techniques and materials. In sectors like oil and gas, bypass valves minimize pressure drops and enhance control over fluid flow, leading to improved operational efficiency. Case studies highlight notable implementations, where facilities have reported up to a 25% decrease in energy consumption by optimizing their bypass valve systems.

In the water treatment industry, a study published by the American Water Works Association indicated that the strategic use of bypass valves can extend the life of infrastructure components by up to 30%. An urban municipality implemented a series of upgrade projects that included state-of-the-art bypass valve systems, resulting in substantial reductions in maintenance costs and downtime during critical operations. These success stories not only emphasize the importance of sophisticated designs but also illustrate how China’s craftsmanship is raising the global standards for bypass valves, making them indispensable in modern industrial applications.

The Future of Bypass Valve Technology and Global Influence

The bypass valve technology is progressing rapidly, with China emerging as a significant player in setting global standards. According to a recent report by MarketsandMarkets, the global bypass valve market is projected to reach USD 1.43 billion by 2025, growing at a CAGR of 4.7%. This growth is largely fueled by advancements in manufacturing techniques and a focus on enhancing the efficiency and reliability of these critical components.

China's craftsmanship in manufacturing bypass valves exemplifies innovation and quality control that are unmatched globally. For instance, the implementation of advanced materials and precision engineering has enabled Chinese manufacturers to produce valves that can withstand extreme pressures and corrosive environments. A study from Technavio highlights that China accounts for over 30% of the total market share, indicating its dominant influence in the valve sector. As these companies continue to invest in R&D and adopt smart technologies, they are not only elevating domestic standards but also shaping the future of bypass valve technology on an international scale.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

The manufacturing of bypass valves has seen a significant transformation in quality control standards, particularly in China. As the global demand for high-performance valves rises, manufacturers are increasingly focusing on meticulous craftsmanship to meet these expectations. This commitment to quality is underscored by stringent processes that encompass every step of production, from material selection to final inspections. By implementing advanced testing methods and adhering to international quality standards, Chinese manufacturers ensure that their bypass valves not only perform reliably but also extend the lifespan of crucial systems.

The manufacturing of bypass valves has seen a significant transformation in quality control standards, particularly in China. As the global demand for high-performance valves rises, manufacturers are increasingly focusing on meticulous craftsmanship to meet these expectations. This commitment to quality is underscored by stringent processes that encompass every step of production, from material selection to final inspections. By implementing advanced testing methods and adhering to international quality standards, Chinese manufacturers ensure that their bypass valves not only perform reliably but also extend the lifespan of crucial systems.